Part 1 – Detailed Testing and Quality Determination of GFRP Rebars

Redefining Reinforcement: The Science Behind GFRP Rebars

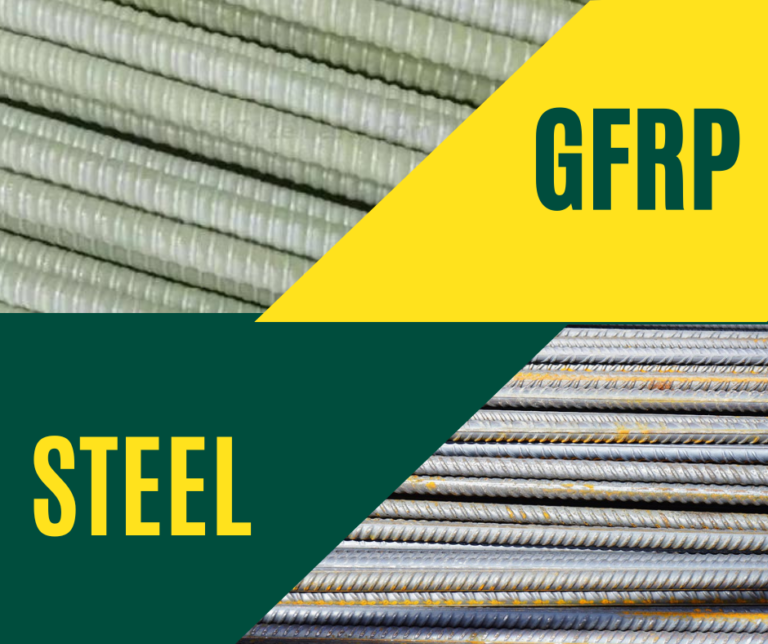

In the ever-evolving field of construction, the call for stronger, more sustainable, and corrosion-free materials continues to grow. Traditional steel has long been the backbone of reinforced concrete — yet its vulnerability to corrosion remains a costly and recurring issue.

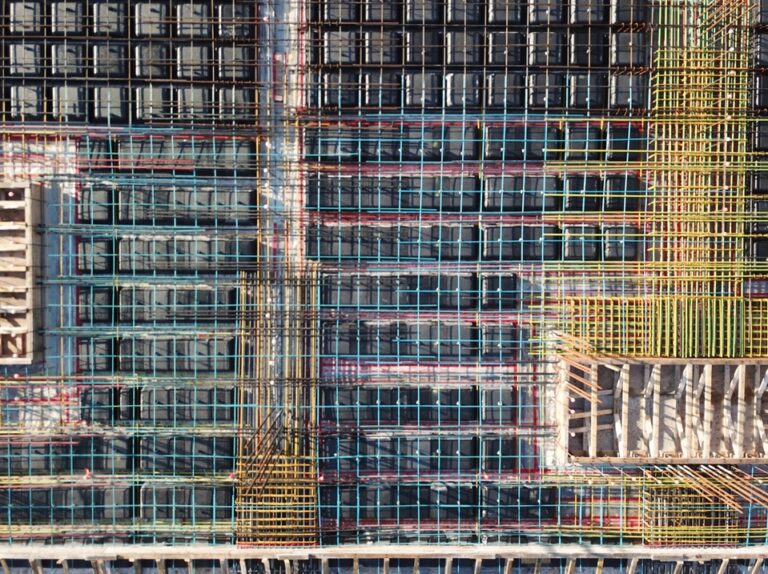

Enter Glass Fiber Reinforced Polymer (GFRP) Rebars — a breakthrough material engineered to outperform steel in durability, longevity, and environmental resilience. Lightweight yet exceptionally strong, GFRP rebars resist rust, deliver superior tensile strength, and offer complete electromagnetic neutrality, making them ideal for bridges, tunnels, marine, and sensitive structures.

At RayBelle Infratrade Corp., our advocacy for sustainable strength goes beyond supply — it’s built on science and global standards. That’s why every SFT-Bar® GFRP Rebar we present complies with internationally recognized testing frameworks under ASTM D7957/D7957M − 22, ASTM D8505-23, and CSA S807:19. These standards set the foundation for what true performance means — ensuring every bar meets stringent criteria for geometric precision, mechanical integrity, and long-term durability.

While GFRP testing capability in Asia remains limited, RayBelle bridges this gap through its partnership with SFTec, Inc., a global leader in FRP reinforcement technologies. Through collaborations with the Université de Sherbrooke (Canada) and the University of Miami (USA) — both internationally accredited by organizations such as ICC, ACI, ASTM, CSA, and FDOT — we ensure that every rebar meets the world’s highest quality and reliability standards.

RayBelle Infratrade Corp. — bringing world-class GFRP innovation to the Philippines, tested and trusted to build the future.