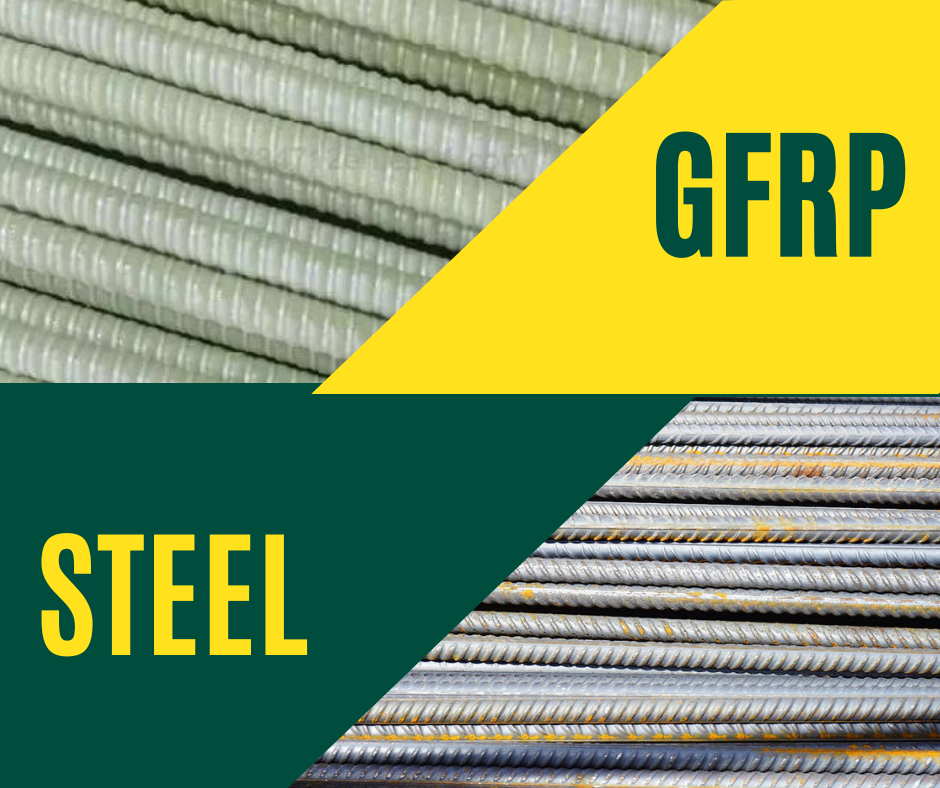

GFRP Rebar vs. Steel Rebar

Choosing the right type of rebar for a construction project can influence the durability, performance, and overall cost of a structure. Glass Fiber Reinforced Polymer (GFRP) rebar and traditional steel rebar are two prominent options, each offering distinct advantages and challenges. Here’s a detailed comparative analysis to help you understand the key differences and make an informed decision.

1. Material Composition and Properties

GFRP Rebar:

- Composition: Made from glass fibers embedded in a polymer resin matrix, providing a composite material that combines strength with lightweight properties.

- Properties: Lightweight, non-corrosive, and non-magnetic. Exhibits high tensile strength and flexibility.

Steel Rebar:

- Composition: Made from carbon steel, often with a ribbed surface to enhance the bond with concrete.

- Properties: Heavy, prone to corrosion, and magnetic. Known for its high tensile strength and ductility.

2. Corrosion Resistance

GFRP Rebar:

- Advantages: Highly resistant to corrosion, making it ideal for use in environments exposed to moisture, salts, or chemicals. This reduces the need for additional protective coatings.

- Maintenance: Low maintenance required due to its inherent corrosion resistance.

Steel Rebar:

- Disadvantages: Prone to rust and corrosion, especially in environments with high humidity or exposure to de-icing salts. Corrosion can lead to concrete spalling and structural degradation.

- Maintenance: Often requires additional protective measures such as coatings or treatments to prevent corrosion.

3. Weight and Handling

GFRP Rebar:

- Advantages: Much lighter than steel rebar, which simplifies handling, transportation, and installation. This can lead to reduced labor and logistics costs on site.

- Impact: Easier to handle and place, which can improve project efficiency.

Steel Rebar:

- Disadvantages: Heavier, which can increase handling and transportation challenges. Requires more labor for installation and can contribute to higher on-site costs.

- Impact: May necessitate additional equipment or manpower to manage and place the rebar.

4. Cost Considerations

GFRP Rebar:

- Initial Cost: Typically higher than steel rebar due to the advanced materials and manufacturing processes involved.

- Long-Term Value: The higher initial investment can be offset by lower maintenance costs and longer service life, especially in corrosive environments.

Steel Rebar:

- Initial Cost: Generally lower than GFRP rebar. A well-established material with widespread availability.

- Long-Term Value: Potentially higher maintenance and repair costs due to corrosion, which can affect the overall cost-effectiveness over time.

5. Thermal and Electromagnetic Properties

GFRP Rebar:

- Advantages: Non-magnetic and provides better thermal insulation, making it suitable for specialized applications such as MRI rooms or data centers.

- Impact: Does not interfere with magnetic fields and can enhance energy efficiency in buildings.

Steel Rebar:

- Disadvantages: Magnetic, which can be a concern in applications requiring minimal electromagnetic interference.

- Impact: May require additional considerations or modifications in projects with specific electromagnetic requirements.

6. Strength and Flexibility

GFRP Rebar:

- Advantages: High strength-to-weight ratio, providing excellent reinforcement with less material. Exhibits flexibility without compromising strength.

- Impact: Effective for reinforcing concrete in a variety of structural applications.

Steel Rebar:

- Advantages: Proven high tensile strength and ductility, well-understood performance characteristics.

- Impact: Long history of use in construction with established design guidelines and standards.

7. Applications

GFRP Rebar:

- Ideal For: Marine structures, parking garages, bridges in corrosive environments, and specialized applications where corrosion resistance is critical.

Steel Rebar:

- Ideal For: General construction applications, including buildings, highways, and bridges, where corrosion resistance is less of a concern or additional protective measures are in place.

Conclusion

Both GFRP and steel rebar offer valuable benefits depending on the specific requirements of a project. GFRP rebar excels in environments where corrosion resistance and lightweight properties are crucial, while steel rebar remains a cost-effective and widely used material with established performance metrics. Understanding the specific needs of your construction project will guide you in selecting the most appropriate reinforcement material.

Are you ready to make an informed decision for your next construction project? Contact us today for expert advice tailored to your needs!